28

2025

-

04

The Importance of Burner Spare Parts: Key Considerations

In the world of industrial processes, burners play a critical role in various applications, including heating, combustion, and energy generation. They are essential components in industries such as manufacturing, power generation, and oil and gas. However, like any mechanical system, burners require maintenance and occasionally need replacement parts to ensure optimal performance. This article explores the importance of burner spare parts and key considerations for their selection and management.

In the world of industrial processes, burners play a critical role in various applications, including heating, combustion, and energy generation. They are essential components in industries such as manufacturing, power generation, and oil and gas. However, like any mechanical system, burners require maintenance and occasionally need replacement parts to ensure optimal performance. This article explores the importance of burner spare parts and key considerations for their selection and management.

Understanding Burner Spare Parts

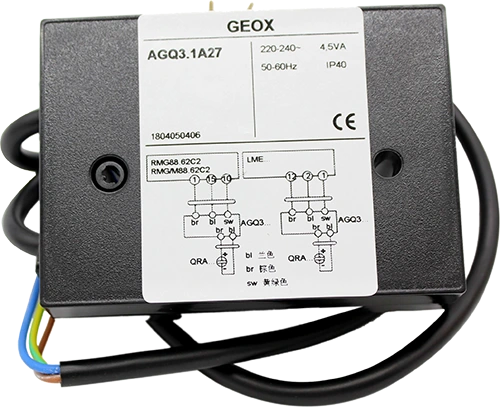

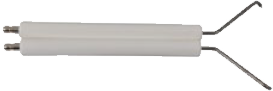

Burner spare parts encompass a wide range of components, including nozzles, igniters, flame rods, valves, and control systems. Each part serves a specific function, contributing to the overall efficiency and safety of the burner. When any of these components fail, it can lead to reduced performance, increased emissions, or even hazardous situations. Therefore, having access to quality spare parts is crucial for maintaining operational continuity and compliance with safety regulations.

The Role of Spare Parts in Efficiency

One of the primary reasons for keeping a stock of burner spare parts is to ensure operational efficiency. A burner that is not functioning at its best can lead to higher fuel consumption, increased emissions, and greater wear and tear on other components. By replacing worn or malfunctioning parts promptly, operators can maintain optimal combustion conditions, which not only improves efficiency but also extends the lifespan of the burner. This proactive approach can result in significant cost savings over time.

Safety Considerations

Safety is paramount in any industrial setting, especially when dealing with combustion processes. Faulty burner parts can lead to dangerous situations, including explosions, fires, or the release of harmful gases. Regular inspection and timely replacement of spare parts can mitigate these risks. Operators must prioritize the quality of spare parts, ensuring that they meet industry standards and are compatible with the specific burner model. Investing in reliable spare parts is an investment in workplace safety.

Choosing the Right Spare Parts

When it comes to selecting burner spare parts, there are several key considerations to keep in mind. First and foremost, compatibility is crucial. Operators should ensure that any spare part they purchase is designed for their specific burner model. Using incompatible parts can lead to further damage or inefficient operation.

Another important factor is quality. It is essential to source spare parts from reputable suppliers who offer high-quality products. Low-quality parts may be cheaper initially but can result in more frequent breakdowns and higher replacement costs in the long run. Additionally, high-quality parts often come with warranties or guarantees, providing further assurance of their reliability.

Cost Management

While it is essential to invest in quality spare parts, cost management is also a significant consideration. Organizations must strike a balance between quality and cost-effectiveness. This involves evaluating the total cost of ownership, which includes not only the purchase price but also installation, maintenance, and potential downtime costs. A thorough cost-benefit analysis can help organizations make informed decisions about which spare parts to stock and when to replace them.

Inventory Management

Efficient inventory management of burner spare parts is another crucial aspect. Organizations should maintain an optimal stock level to ensure that they can respond quickly to maintenance needs without overstocking, which can tie up valuable resources. Implementing an inventory management system can help track usage patterns, predict future needs, and streamline the ordering process. This ensures that spare parts are readily available when required, minimizing downtime and maximizing productivity.

Supplier Relationships

Building strong relationships with reliable suppliers can also enhance the management of burner spare parts. Suppliers who understand the specific needs of the industry can provide valuable insights into product selection, availability, and lead times. Collaborating with suppliers can lead to better pricing, quicker access to parts, and even opportunities for custom solutions. Establishing a partnership with a trusted supplier can ultimately improve operational efficiency and reliability.

Training and Knowledge

Lastly, it is essential to invest in training and knowledge for personnel responsible for burner maintenance and spare parts management. Proper training ensures that staff are aware of the importance of using quality parts and the implications of using substandard alternatives. Additionally, having knowledgeable personnel can help in diagnosing issues more accurately, leading to more effective maintenance practices.

Conclusion

In conclusion, burner spare parts are a critical aspect of maintaining the efficiency, safety, and longevity of combustion systems in various industrial applications. Understanding the importance of these parts, selecting them wisely, managing inventory effectively, and fostering supplier relationships are key considerations that can significantly impact operational success. By prioritizing the quality and availability of burner spare parts, organizations can ensure that their processes run smoothly, safely, and efficiently, ultimately contributing to their bottom line.

Related news