12

2021

-

11

Turkey ISK-SODEX Exhibition

When it comes to maintaining the efficiency and safety of heating systems, the replacement of burner parts is a critical aspect that should not be overlooked. Burners are the heart of any heating system, whether it be for residential, commercial, or industrial applications. Understanding when and how to replace burner parts can enhance performance, prolong equipment life, and ensure safety. This article will explore the key considerations for burner parts replacement, including signs of wear, types of parts, the importance of quality, and maintenance practices.

When it comes to maintaining the efficiency and safety of heating systems, the replacement of burner parts is a critical aspect that should not be overlooked. Burners are the heart of any heating system, whether it be for residential, commercial, or industrial applications. Understanding when and how to replace burner parts can enhance performance, prolong equipment life, and ensure safety. This article will explore the key considerations for burner parts replacement, including signs of wear, types of parts, the importance of quality, and maintenance practices.

One of the first considerations for burner parts replacement is recognizing the signs of wear and tear. Burners can exhibit various symptoms that indicate it is time for a replacement. Common signs include inconsistent flame patterns, excessive noise during operation, increased emissions, and a decrease in heating efficiency. Additionally, if the burner frequently shuts off or fails to ignite, it may be a clear indication that certain parts need to be replaced. Regular inspections and monitoring can help identify these issues early on, preventing more extensive damage and costly repairs.

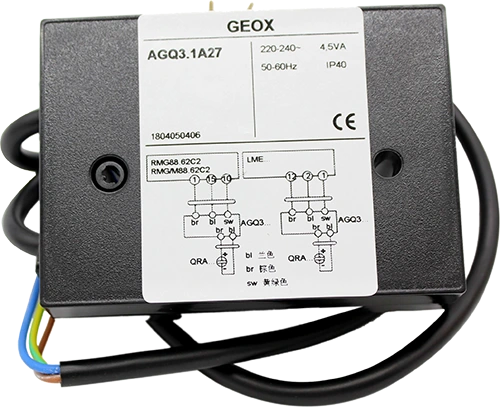

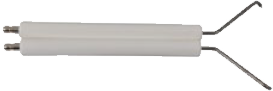

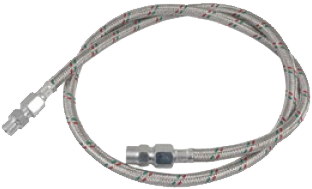

Another important aspect to consider is the type of burner parts that may need replacement. Burners consist of several components, including fuel valves, igniters, burners heads, and control systems. Each of these parts plays a crucial role in the overall functioning of the burner. For instance, a malfunctioning fuel valve can lead to improper fuel delivery, while a faulty igniter can cause ignition failures. Understanding the specific parts that are prone to wear can help in planning maintenance schedules and anticipating replacements.

When it comes to replacing burner parts, quality should never be compromised. The use of original equipment manufacturer (OEM) parts is highly recommended as they are designed to meet the specific standards and requirements of the burner. OEM parts ensure compatibility, reliability, and optimal performance. While it may be tempting to opt for cheaper aftermarket parts, they can often lead to subpar performance, increased energy consumption, and a higher risk of malfunction. Investing in high-quality parts not only enhances the efficiency of the burner but also reduces the likelihood of future replacements.

In addition to quality, it is essential to consider the expertise required for burner parts replacement. Proper installation is crucial to ensure that the burner operates safely and efficiently. While some individuals may attempt to perform replacements themselves, it is often best to consult with a qualified technician. Professionals possess the necessary knowledge and experience to handle the complexities involved in burner maintenance and replacement. They can also conduct thorough inspections to identify any underlying issues that may not be immediately apparent, ensuring that all aspects of the burner are functioning optimally.

Moreover, regular maintenance practices play a vital role in extending the lifespan of burner parts. Implementing a routine maintenance schedule can help identify potential problems before they escalate. This includes cleaning the burner components, checking for signs of corrosion, and ensuring that all connections are secure. Additionally, keeping an eye on fuel quality and ensuring that the burner is operating within its specified parameters can significantly reduce wear and tear on parts. By prioritizing maintenance, the need for frequent replacements can be minimized, ultimately saving time and money.

Another consideration is the environmental impact of burner operation. As regulations around emissions become increasingly stringent, it is essential to ensure that burner parts are replaced in a manner that complies with local environmental standards. Upgrading to more efficient parts can reduce emissions and enhance the overall sustainability of the heating system. Additionally, many modern burner components are designed with energy efficiency in mind, contributing to lower operational costs and a reduced carbon footprint.

Lastly, it is crucial to keep records of all burner parts replacements and maintenance activities. Documentation serves as a valuable reference for future maintenance and can help track the performance of the burner over time. This information can be particularly useful when assessing the need for further replacements or upgrades, as well as providing insights into the overall efficiency of the heating system.

In conclusion, the replacement of burner parts is a significant aspect of maintaining a safe and efficient heating system. By being aware of the signs of wear, understanding the types of parts that may need replacement, prioritizing quality, and ensuring proper installation, individuals and organizations can enhance the performance and longevity of their burners. Regular maintenance and consideration of environmental impacts further contribute to the overall efficiency and sustainability of heating systems. By taking these considerations into account, users can ensure that their burners operate at peak performance while minimizing the risk of malfunctions and costly repairs.

Related news